Ring engraving by experts in Scotland

Ring production

There are many ways to make a signet ring; my preferred method is to make a bespoke ring for each client in order to exactly match the individual's requirements.

- To make one of my "bespoke" signet rings, a blank ring shape is cut from a sheet of the chosen precious metal

- The ring is then shaped and rounded from the flat blank, then made to the correct finger size and secured by soldering. The ring is then carefully shaped with files and buffs to give, in my opinion, a beautiful classic signet ring

- The inside of the ring is now prepared for *hallmarking at the Edinburgh Assay Office

- Hallmarking is a guarantee, in law, to the quality of the precious metal. The mark is stamped into the shank of the ring along with a special punch mark, "the drillstock", which is exclusive to fellows of the Institute of Professional Goldsmiths. It denotes the article is made to the highest standards expected of the Institute

- Next, the finish is further refined, and the shape perfected, using fine grade files and polishing. If it is a stone-set ring, the stone will be set at this stage

- Only now, after this careful preparation, can the engraving begin

Seal engraving

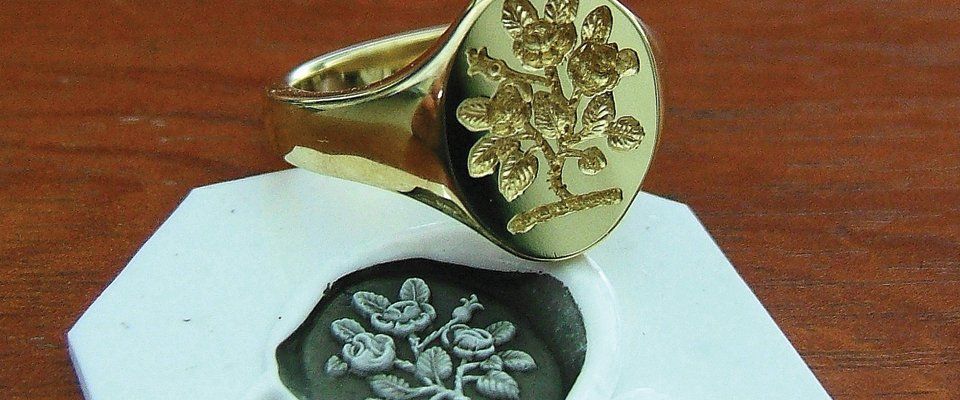

“A Seal” is wax impressed with a design and attached to a document as evidence of authenticity. “Seal engraving” is the cutting of the design into the ring, desk stamp etc., which is used to achieve the wax impression. Consequently, the design has to be cut into the ring in reverse to create a wax impression which is recognisable. Also, every design has to be unique thus avoiding forgery.

When Mr. Oliver is engraving a seal onto a gold signet ring, he dusts the surface of the ring with a fine layer of powder. Then using a feather, he draws the design in reverse, onto the head of the ring. When the design is to Mr. Oliver’s liking he draws a more permanent design onto the ring using a scriber.

The next stage is to cut, by hand, into the signet ring using the various wooden-handled tools, which Mr. Oliver has made himself over the years. The steel blade of each tool has been handcrafted to fit a specific type of job. Eventually, after many hours of work, the completed ring is pressed into soft modelling clay to show an impression of the finished article. This is the first time that Mr. Oliver is able to see, in detail, how the design looks.

The ring is then brushed, cleaned and a final wax impression is taken. After the wax is taken, the head of the ring is lapped to give a mirror clean finish.

Seal engraving onto a stone signet ring is a completely different skill. Mr. Oliver dusts the surface of the ring as before, but instead of cutting into the ring with steel tools, he uses miniature wheels which are attached to a lathe. Mr. Oliver holds the stone head of the signet ring against the turning wheel and, applying pressure, carves away the stone.

Using these techniques Mr. Oliver is able to create the most intricate designs. A full Coat of Arms is reproduced in all its detail from a large design on an A4 sized piece of paper, onto even the smallest 11mm x 9mm oval signet ring.

Lapping and polishing

A "lap" is a wheel with a diameter of 12 inches, made of an alloy of lead and tin. The working surface is highly polished and absolutely flat.

"Lapping" produces a mirror finish on the head of a signet ring or any other item requiring a highly reflective flat surface. To lap a signet ring, Neil Oliver applies special oil and grinding agents to the surface of the lap and then holds the signet ring at exactly the correct angle, against the treated lap, which is turning at high speed. With the application of gentle pressure, the surface of the ring is polished. Lapping is very skilled work; "lappers" in the jewellery trade have taken years to acquire the necessary techniques, and such individuals are highly regarded.

Polishing is the final stage of ring production. Round soft buffs, of approx. 4 inches diameter, made of layers of calico cloth called "mops" that turn at high speed on a polishing motor; jewellers’ rouge is applied to the mop, and the ring is held against the spinning mop to ensure a beautiful deep glowing finish.

Beautiful signet rings are available in:

- Aberdeen

- Inverness

- Glasgow

- Forres

- Edinburgh

- Across the UK

- And Worldwide